In the demanding landscape of modern manufacturing, the ability to produce high-quality, custom components is not just an advantage—it’s a necessity. Industries from aerospace to medical devices rely on parts tailored to exact specifications, where failure is not an option. At the heart of this capability lies Precision CNC Machining, a technology that masterfully combines digital design with subtractive manufacturing to create complex, non-standard parts with unparalleled accuracy and repeatability .

This article explores how precision CNC machining serves as the cornerstone for custom manufacturing, enabling innovation across sectors by turning intricate designs into tangible, high-performance components.

1. The Synergy of CNC Technology and Customization

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process can control a range of complex machinery, from grinders and lathes to mills and routers, enabling the creation of highly complex shapes that would be almost impossible to achieve manually .

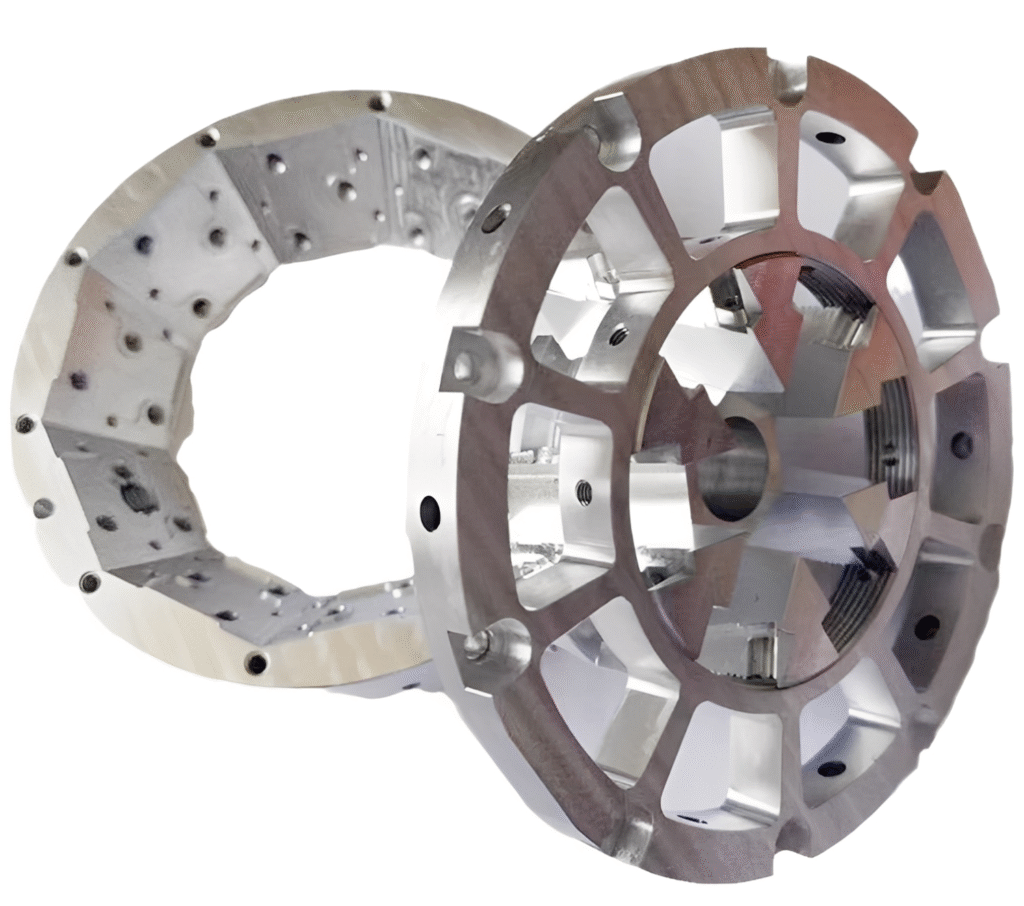

The term “non-standard” or “custom” parts refers to components designed to meet unique geometric, material, or functional requirements not fulfilled by off-the-shelf solutions. Precision CNC machining is uniquely suited for this task because it offers:

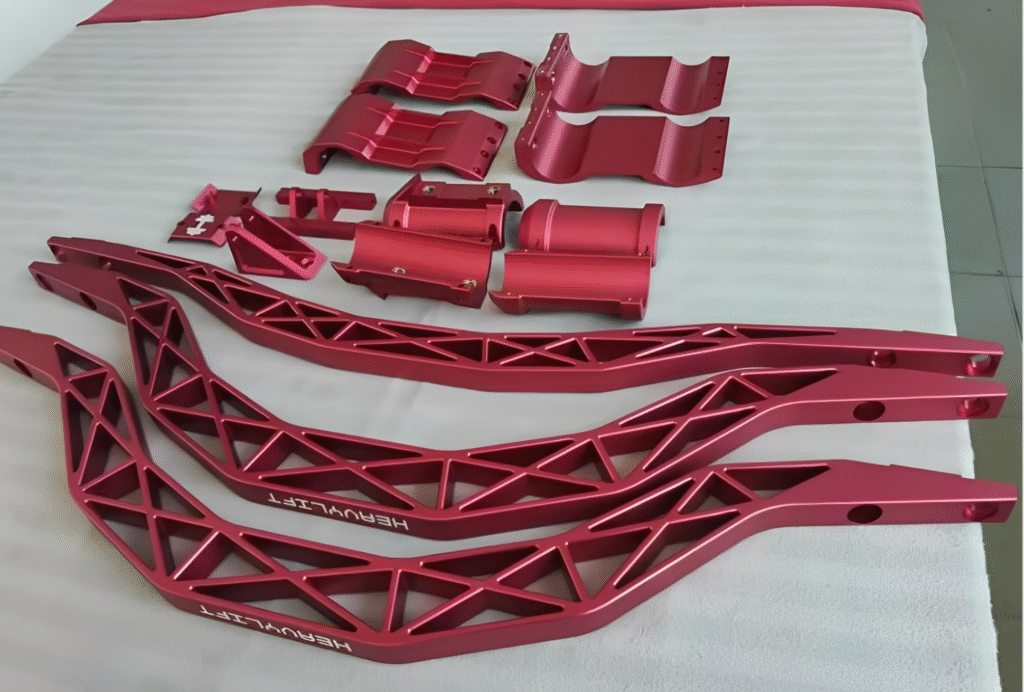

- Design Freedom: Advanced CAD/CAM software translates even the most complex 3D models into machinable instructions, allowing for immense design flexibility .

- Material Versatility: CNC systems can work with a vast array of materials, including metals like aluminum, stainless steel, and titanium, as well as engineering-grade plastics and composites .

- Cost-Effectiveness for Low to Mid Volumes: Unlike traditional manufacturing methods that require expensive molds, CNC customization is ideal for prototypes, small batches, and on-demand production without significant tooling costs .

2. The Journey of a Custom Part: From Digital Blueprint to Precision Component

The creation of a precision non-standard part follows a meticulous, technology-driven workflow.

- Step 1: Design and Engineering (CAD/CAM) The process begins with a detailed Computer-Aided Design (CAD) model. This digital blueprint defines every dimension and feature of the part. Subsequently, Computer-Aided Manufacturing (CAM) software converts the CAD model into a set of instructions (G-code) that the CNC machine will follow, specifying the cutting tool paths, speeds, and feed rates .

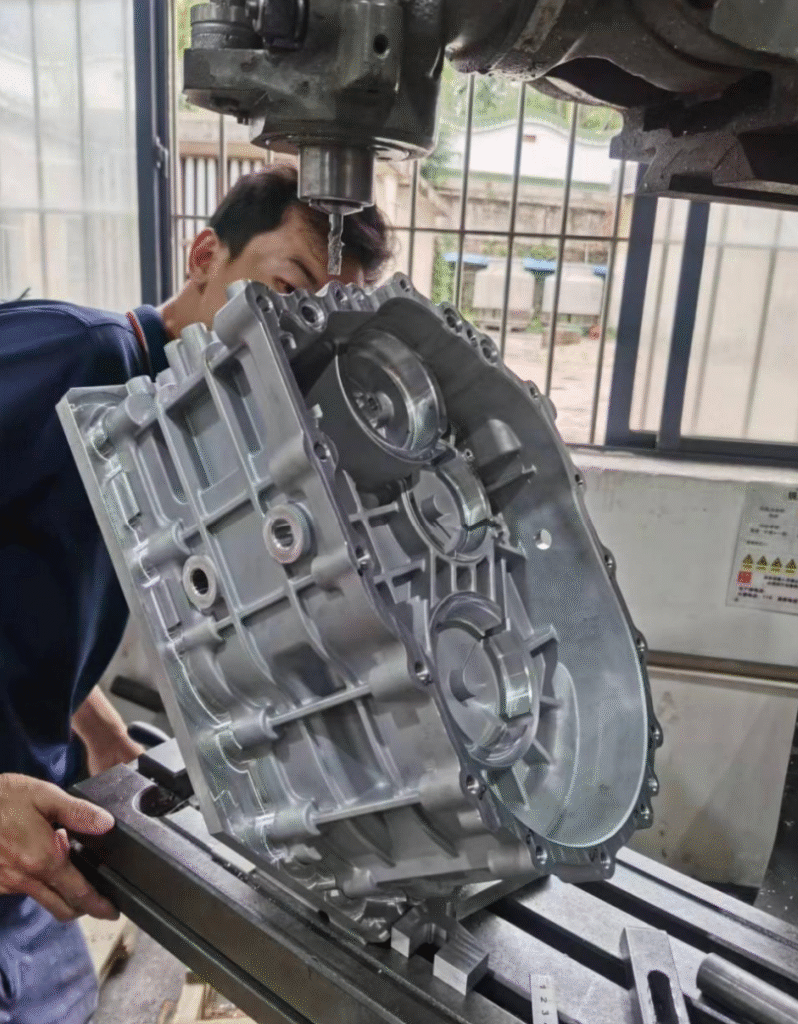

- Step 2: CNC Machining Processes Two primary CNC processes are often employed:

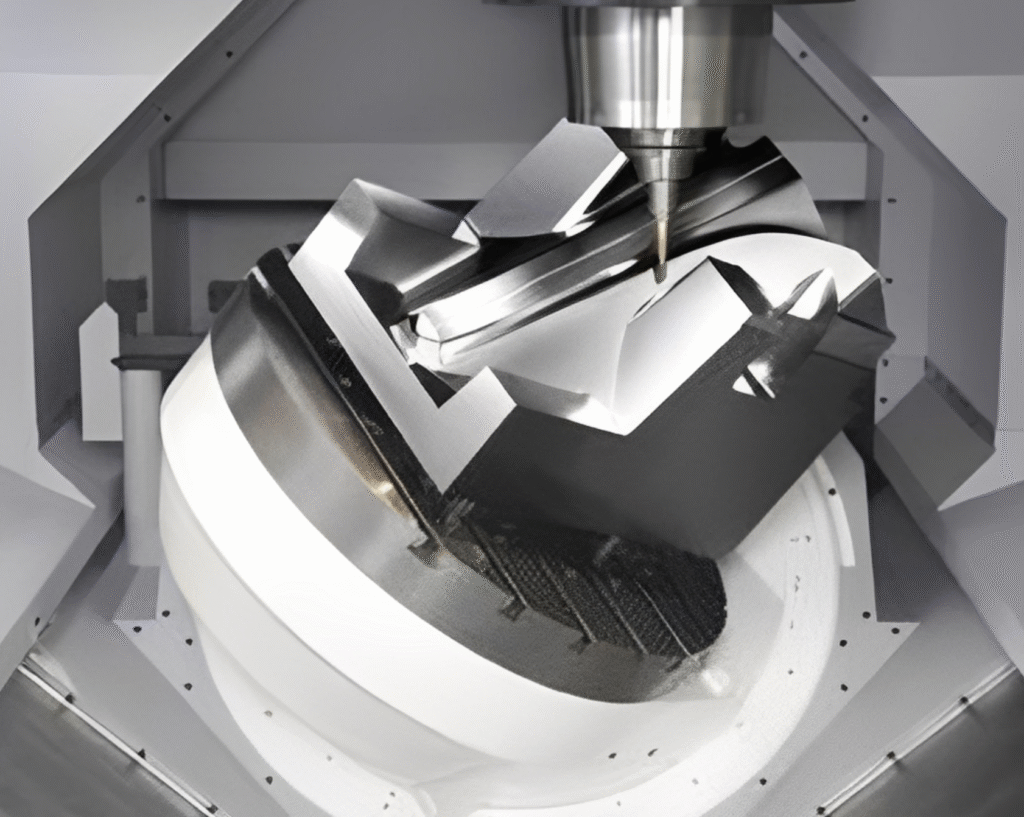

- CNC Milling: This process uses rotary cutting tools to remove material from a stationary workpiece. It is exceptionally adept at creating complex geometries, slots, pockets, and 3D contours. Multi-axis (e.g., 5-axis) milling machines can produce intricate shapes in a single setup, minimizing errors and saving time .

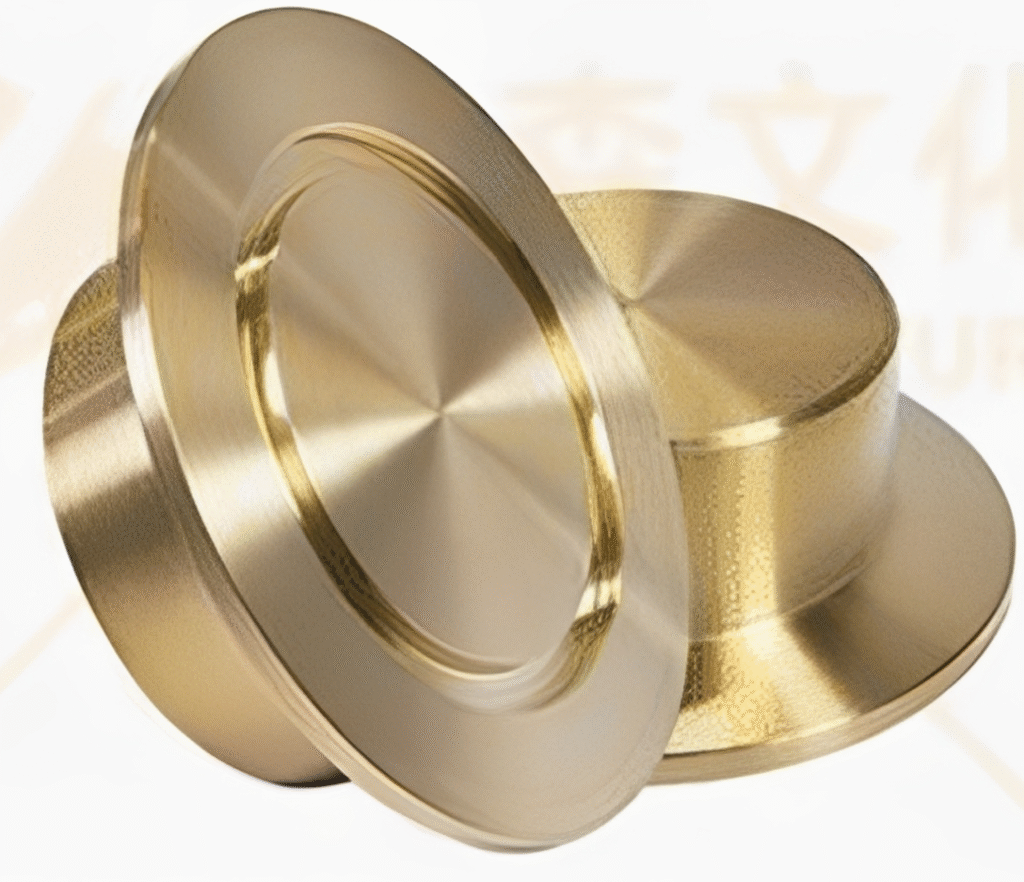

- CNC Turning: Used for cylindrical parts, turning involves rotating the workpiece while a single-point cutting tool removes material. It is ideal for producing shafts, bolts, and connectors with high concentricity .

- Step 3: Achieving Micron-Level Precision The term “precision manufacturing” is quantified here. Achieving tolerances as tight as ±0.001 inches or even finer requires more than advanced machinery . It demands:

- Thermal Stability: Workshop temperature must be meticulously controlled, as even slight variations can cause materials to expand or contract, affecting dimensions. A controlled environment around 20°C is often essential for micron-level accuracy .

- Advanced Metrology: Finished parts are rigorously inspected using coordinate measuring machines (CMMs) and other high-precision tools to validate that every dimension meets the specified tolerances .

3. Key Applications: Where Precision Meets Innovation

The application of precision CNC machining for non-standard parts is critical in several high-tech industries:

- Aerospace: Components like turbine blades and structural brackets must be lightweight yet incredibly strong, capable of withstanding extreme conditions. Precision CNC machining ensures these parts meet the rigorous safety and performance standards of the industry .

- Medical: The production of surgical instruments, orthopedic implants, and diagnostic equipment demands ultra-high precision and exceptional surface finishes. Furthermore, the ability to machine biocompatible materials is crucial for patient safety .

- Automotive: From high-performance engine components and custom fixtures for racing vehicles to prototyping new designs, CNC machining enables rapid innovation and optimization for better efficiency and safety .

4. Choosing the Right Precision Manufacturing Partner

Selecting a competent CNC machining partner is vital for the success of your project. Key factors to consider include:

- Technical Expertise and Experience: Look for a provider with a proven track record in your specific industry and with the types of materials and geometries you require .

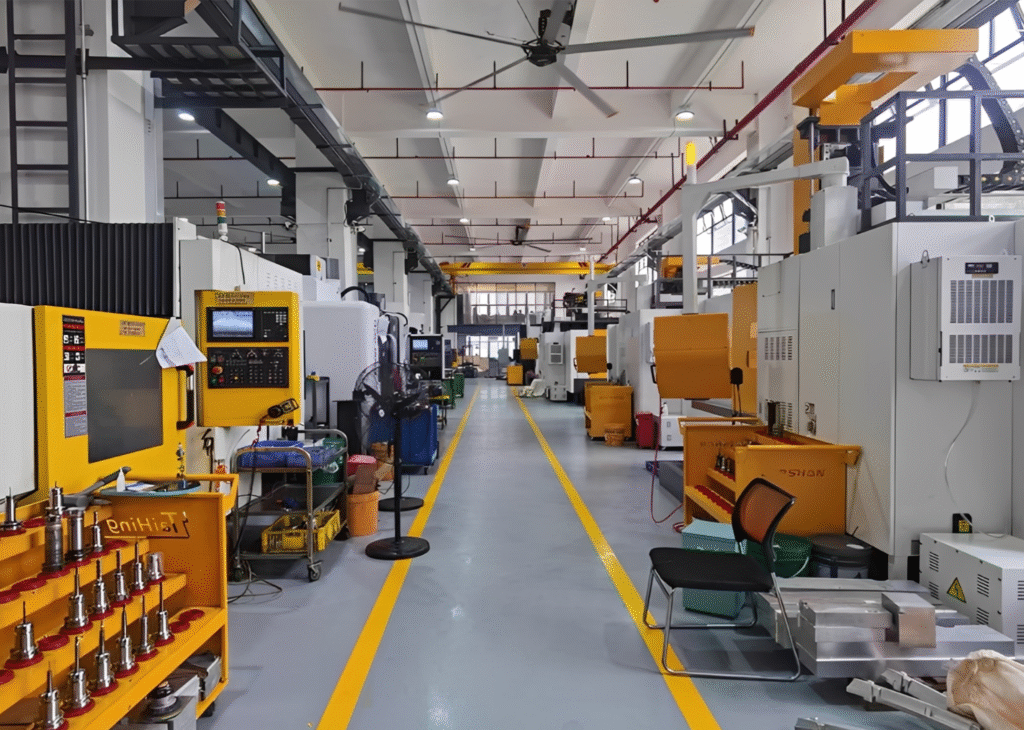

- Equipment Capabilities: Ensure the supplier possesses modern, multi-axis CNC machines and supporting technologies like CMMs to guarantee quality .

- Quality Certifications: Partners with certifications like ISO 9001 demonstrate a commitment to consistent quality and continuous improvement .

5. The Future of Precision Manufacturing

The field of precision manufacturing is continuously evolving. Emerging trends like AI-driven process optimization, IoT-enabled machines for real-time monitoring, and hybrid manufacturing (which combines additive and subtractive techniques) are pushing the boundaries of what’s possible in CNC customization, promising even greater efficiency and capabilities .

Conclusion

Precision CNC machining is the fundamental engine that powers the creation of reliable, high-performance non-standard parts. By leveraging this technology, businesses can navigate the complexities of modern design requirements, accelerate product development, and maintain a competitive edge in their markets.

Ready to leverage precision CNC machining for your custom part needs? Partner with a expert who can guide you from design to delivery. Contact us today to discuss your project and receive a quote.