In the realm of modern manufacturing, low volume CNC machining has become an indispensable method for producing.In today’s fast-evolving manufacturing landscape, the demand for highly customized, non-standard parts is growing across industries such as aerospace, automotive, medical devices, and robotics. Unlike standardized components, non-standard parts require unique geometries, tight tolerances, and specialized materials—making traditional manufacturing methods often inadequate. This blog explores how precision CNC machining addresses these challenges while delivering efficiency, accuracy, and scalability for small-batch production.

1. Understanding Non-Standard Parts and Their Complexities

Non-standard parts, also known as custom or bespoke components, are designed to meet specific requirements not found in standard catalogs. These parts often feature:

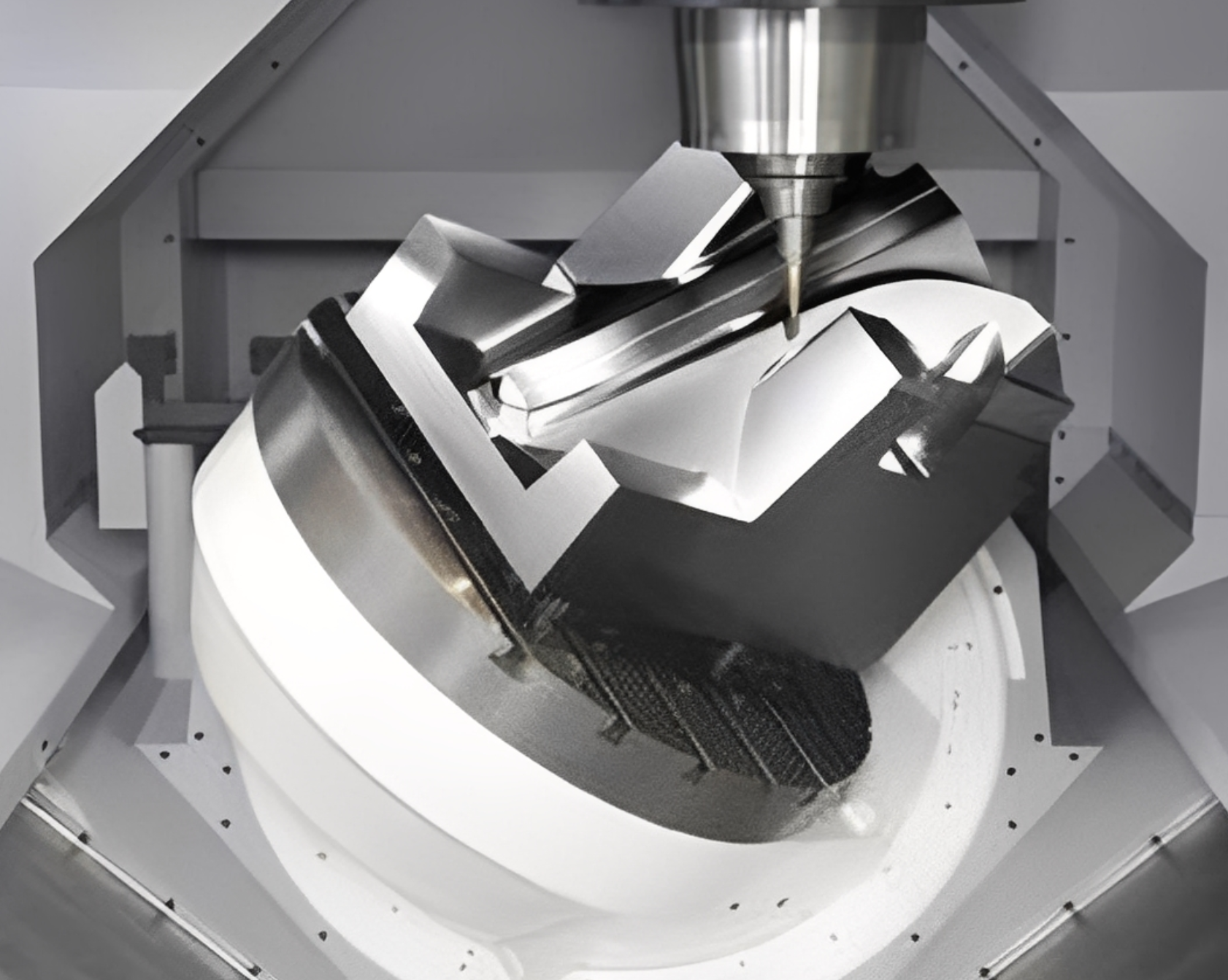

- Intricate geometries (e.g., turbine blades, complex housings).

- Extreme precision requirements (tolerances as tight as ±0.005 mm).

- Demanding material properties (e.g., titanium alloys, superalloys, or composites) .

Producing such components with conventional methods can lead to:

- High costs and long lead times due to complex setups.

- Tool wear and material stress from machining hard materials.

- Inconsistencies in quality without advanced process control .

2. Why CNC Machining Is Ideal for Non-Standard Parts

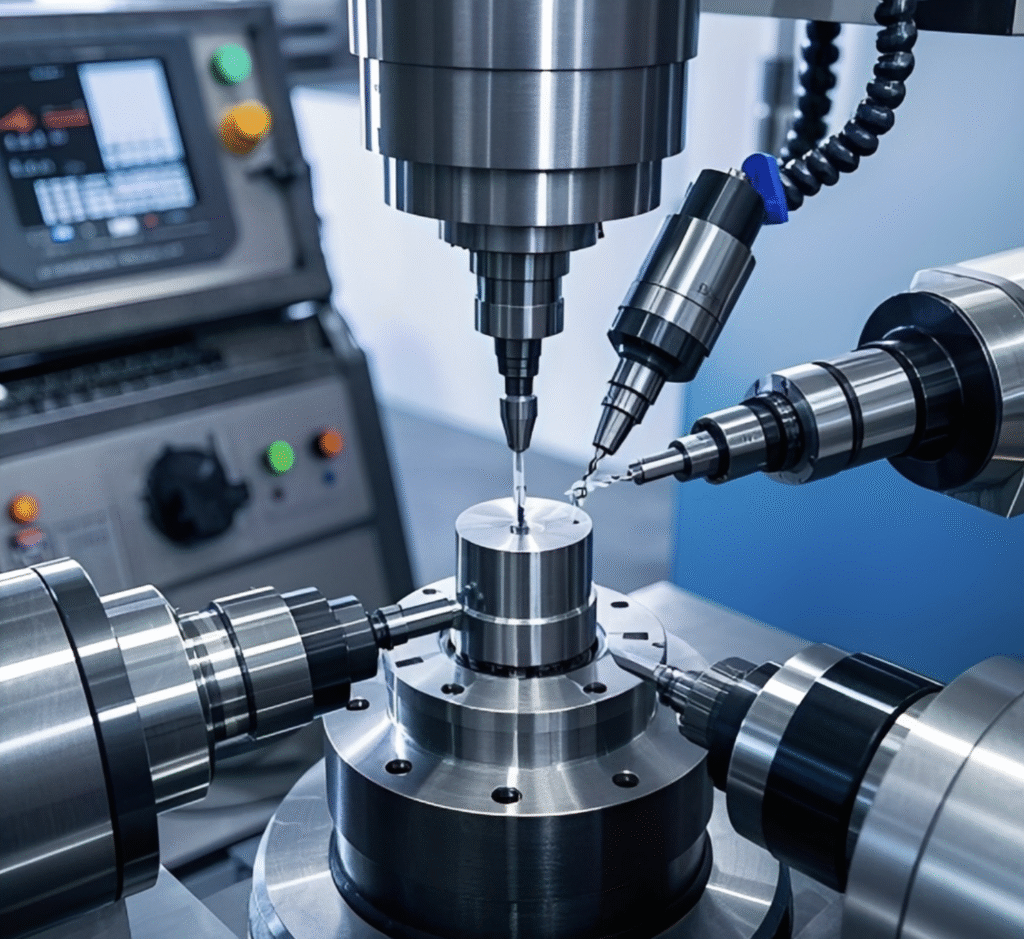

CNC (Computer Numerical Control) machining combines subtractive manufacturing with computer-guided precision, making it a cornerstone technology for custom parts. One of the key benefits of low volume CNC machining is its flexibility.

Key advantages include:

A. Precision and Flexibility

- CNC turning and milling achieve tolerances up to ±0.01 mm, critical for aerospace and medical applications .

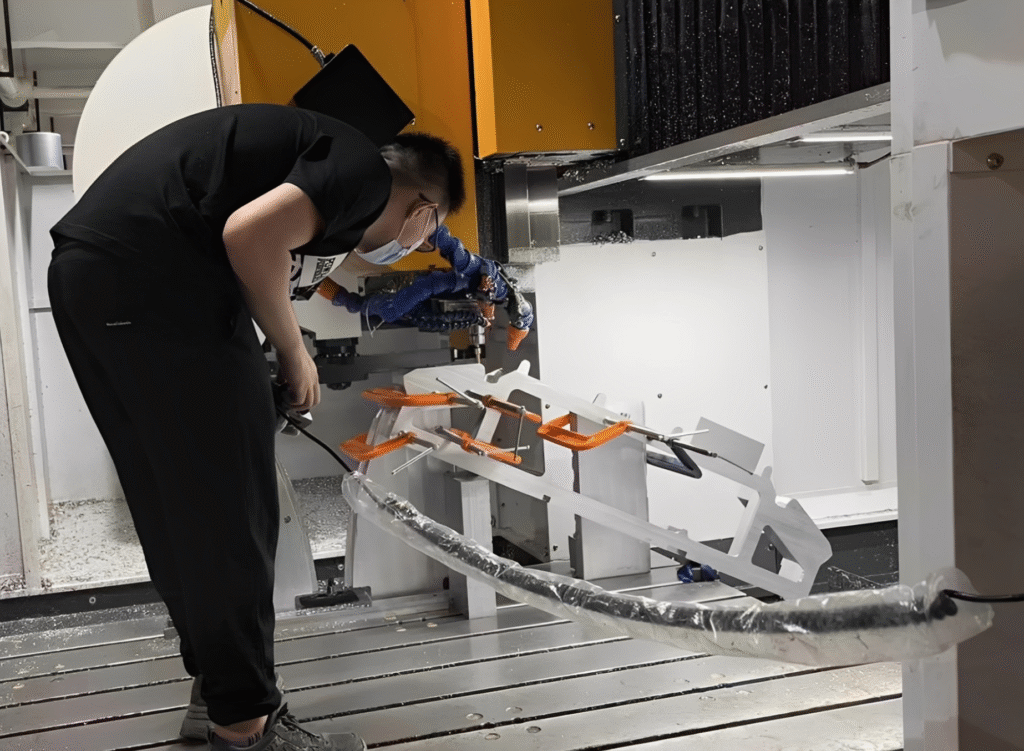

- Multi-axis CNC machines (e.g., 5-axis systems) can produce complex 3D shapes in a single setup, reducing errors and handling features like undercuts, tapered sections, and deep grooves .

B. Efficiency in Small-Batch Production

- Unlike injection molding or stamping, CNC machining requires no expensive molds, making it cost-effective for prototypes or small batches (1–500 units) .

- Digital workflows (CAD/CAM) allow rapid design iterations—ideal for industries like automotive prototyping or medical device testing .

C. Material Versatility

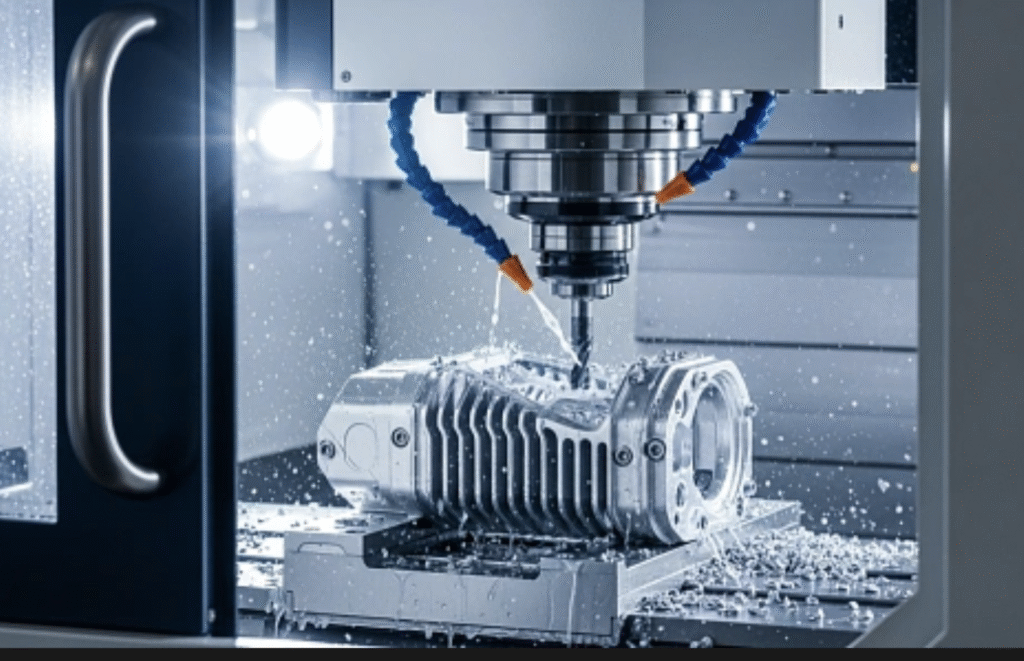

- CNC systems work with metals (aluminum, stainless steel, titanium), plastics (ABS, Nylon), and composites, enabling tailored solutions for diverse needs .

3. Key Challenges in CNC Machining Non-Standard Parts

Despite its advantages, CNC machining of custom parts faces hurdles:

| Challenge | Impact | Solution |

|---|---|---|

| Complex Programming | Longer setup times and potential errors | Use AI-driven CAM software to optimize tool paths . |

| Tool Wear | Reduced accuracy and surface finish | Advanced coatings and real-time tool monitoring . |

| Material Stress | Warping or defects in delicate parts | Controlled machining environments and adaptive cooling . |

| High Costs | Limited budget for low-volume runs | Lean manufacturing and just-in-time inventory . |

4. Innovative Solutions for Enhanced Efficiency

To overcome these challenges, leading manufacturers adopt integrated approaches:

A. Hybrid Manufacturing: CNC + Silicone Molding

- For small batches (1–50 units), combining CNC-machined master molds with silicone vacuum casting replicates parts at ±0.1 mm accuracy in 3–5 days .

- This reduces costs by up to 40% compared to traditional tooling, ideal for automotive prototypes or custom robotics components .

B. Smart Manufacturing and IoT

- AI-powered analytics predict tool wear and optimize cutting parameters, boosting efficiency .

- Digital twins simulate machining processes, minimizing trial runs and material waste .

C. Strict Quality Control

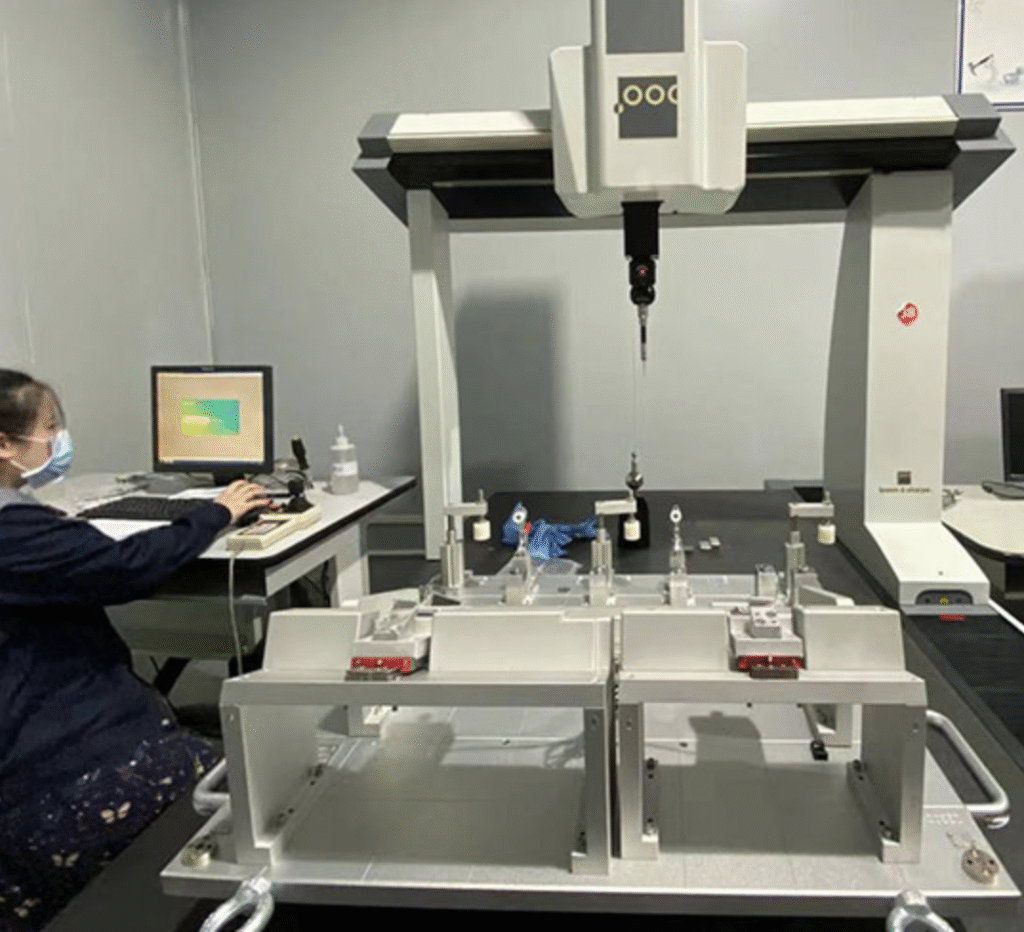

- Coordinate measuring machines (CMMs) and laser scanners verify dimensional accuracy .

- Non-destructive testing (e.g., X-ray) detects internal defects without damaging parts .

5. Case Study: Automotive Component Prototyping

A robotics startup needed 20 custom actuator housings with complex internal channels. Traditional methods quoted 4 weeks and $5,000 per unit. By leveraging 5-axis CNC machining and silicone molding:

- Lead time dropped to 5 days, with per-unit costs reduced by 35%.

- Post-process CMM validation ensured 99.8% dimensional compliance .

6. Future Trends in CNC Non-Standard Machining

- AI-Driven Design: Generative AI creates optimized part geometries for weight reduction and performance .

- Sustainable Practices: Energy-efficient CNC systems and recyclable materials support green manufacturing .

- Multi-Material Hybrid Printing: Combining CNC with 3D printing enables parts with varied material properties .

7. Conclusion: Partnering for Precision

CNC machining remains indispensable for non-standard parts, offering unparalleled precision and flexibility. By embracing technologies like silicone molding, AI, and digital twins, manufacturers can achieve faster turnaround times, lower costs, and higher quality—key to thriving in competitive markets.

Ready to bring your custom part designs to life?Contact us today for a free consultation on CNC machining solutions tailored to your needs.

This blog post is optimized for SEO with keywords like “CNC non-standard parts,” “precision machining,” and “small-batch production.” It balances technical depth with readability, making it suitable for engineers, product designers, and manufacturing decision-makers. Let me know if you’d like to adapt it for specific industries or add a call-to-action for your services!